Top Sound Insulation Techniques for Roofing

Are you tired of the constant noise disturbances in your home? Discover the top sound insulation techniques that can transform your roofing system into a haven of peace and tranquility. In this article, we will explore effective methods to minimize external noise and create a serene living environment.

Contents

The Impact of Noise Pollution

1. Understanding the Effects of Noise Pollution

Noise pollution can have detrimental effects on our health and well-being. From traffic sounds to construction noises, the constant exposure to external noise can lead to stress, sleep disturbances, and reduced productivity. Implementing sound insulation techniques for your roof can significantly improve your quality of life by reducing noise infiltration.

Effective Sound Insulation Techniques

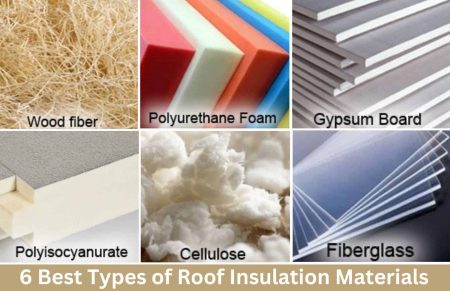

1. Insulating Materials for Soundproofing

Proper insulation is the foundation of soundproofing your roof. Choose high-quality insulation materials, such as fiberglass or cellulose, that have excellent sound-absorbing properties. These materials create a barrier that prevents sound waves from penetrating your home, resulting in a quieter indoor environment.

2. Acoustic Underlayment

Installing an acoustic underlayment beneath your roofing system can further enhance sound insulation. These specialized underlayments are made of dense materials that absorb and dampen noise vibrations, preventing them from passing through to the interior. Acoustic underlayments are particularly effective in reducing impact noise, such as footsteps or falling objects.

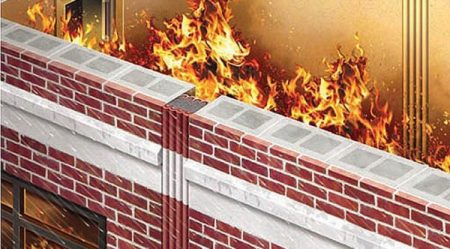

3. Sealing and Weatherstripping

Properly sealing any gaps, cracks, or joints in your roof structure is essential for effective sound insulation. Use weatherstripping materials to seal openings and ensure a tight seal. By eliminating potential entry points for noise, you can significantly reduce sound transmission and create a more peaceful living space.

4. Decoupling Techniques

Decoupling techniques involve creating a separation between the ceiling and the roof structure. By using resilient channels or acoustic hangers, the transfer of sound vibrations from the roof to the interior is minimized. This method is highly effective in reducing airborne noise, such as voices or music.

5. Sound-Absorbing Roofing Materials

Choosing sound-absorbing roofing materials can also contribute to sound insulation. Opt for materials such as clay tiles, rubber shingles, or metal roofs with sound-dampening properties. These materials help reduce external noise and create a quieter environment inside your home.

Frequently Asked Questions

Q1: Can sound insulation techniques completely eliminate all external noise? A1: While sound insulation techniques significantly reduce noise levels, it is challenging to eliminate all external noise completely. However, these techniques create a substantial reduction, ensuring a quieter and more comfortable living space.

Q2: Are sound insulation techniques only applicable to residential properties? A2: No, sound insulation techniques are beneficial for various properties, including residential, commercial, and industrial buildings. They help create a peaceful environment, enhance productivity, and improve overall comfort.

Q3: How long does it take to install sound insulation techniques for roofing? A3: The installation time depends on several factors, such as the size of the roof, chosen techniques, and complexity of the project. It is best to consult with professionals to get an accurate estimate based on your specific requirements.

Q4: Can sound insulation techniques also improve energy efficiency? A4: Yes, many sound insulation techniques, such as proper insulation and sealing, provide additional benefits like improved energy efficiency. These techniques help minimize heat loss during winter and prevent heat gain during summer, resulting in energy savings and reduced utility bills.

Q5: Do sound insulation techniques require regular maintenance? A5: Sound insulation techniques generally require minimal maintenance. Regular inspections and cleaning to remove debris and ensure proper sealing are recommended. Consult the manufacturer’s guidelines or professionals for specific maintenance requirements.